Capacity Calculation

Plus Planning is capable of flexible, adaptive finite capacity planning that takes into account real-life requirements of the production site. Some constraints considered in finite capacity planning are presented below;

- Holiday Calendar Setting: Official holidays or facility-specific holidays can be defined.

- Resource-Based Downtimes: Downtimes covering a specific time interval of the shift can be defined for resources.

-

Scenario-Based Finite Capacity Planning;

- Scenario-Specific Downtimes: General downtimes for the entire facility or scenario-specific downtimes for individual resources can be defined within a scenario. For example, downtimes due to fire drills or inspections.

- Overtime Approval: Overtime can be enabled or disabled depending on approval within the scenario. With parametric control of this feature, finite capacity considers the overtime capacity defined for each scenario.

- Skill-Based Resource Efficiency: Finite capacity planning can be made more realistic by considering personnel experience (competency). For example, the skills of a master and an apprentice can be evaluated differently, taking into account their ability to perform tasks in capacity calculations.

- Operation During Standard Downtimes: It can be specified whether resources will operate during standard downtimes.

-

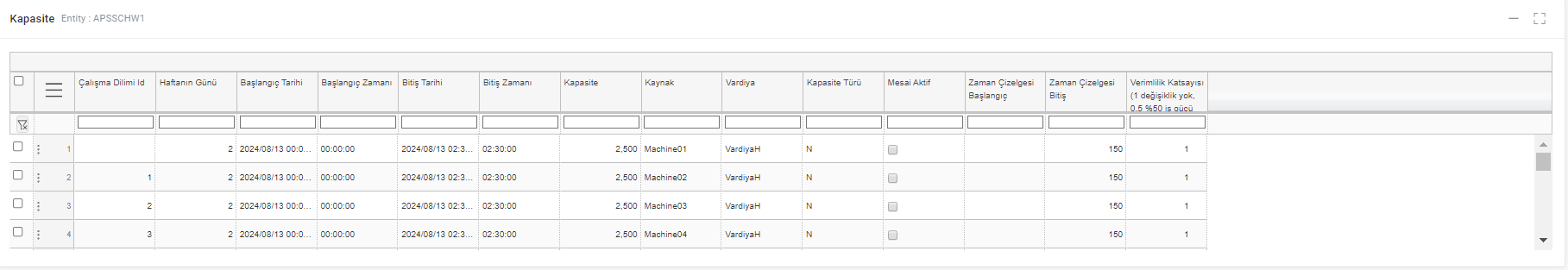

Shift-Based Planning Horizon:

The planning for each facility can be segmented as desired. These segments, referred to as shifts, can be customized and linked to the resources within the facility.

These customizations can be listed as follows;

- Shift-Based Work/Overtime Definition: Work hours and overtime hours can be defined separately for each shift created for each facility.

- Shift-Based Standard Downtime Definitions: Standard downtimes such as lunch and tea breaks can be defined for each shift.

- Resources Working/Not Working During Shifts: It can be determined in which shifts a resource will work.

-

Integration with ERP Software for Finite Capacity Planning:

Some integration items are as follows;

- Machine and mold maintenance plan integration and

- With the integration of the personnel tracking system, it is possible to plan finite capacity according to the personnel who are on leave or absent.