Detailed Material & Tools Usage Analysis

Detailed Material and Tool Usage Analysis is a feature that comprehensively evaluates the use of materials and tools in production processes. This analysis was developed to increase material and tool efficiency, reduce costs and optimize processes.

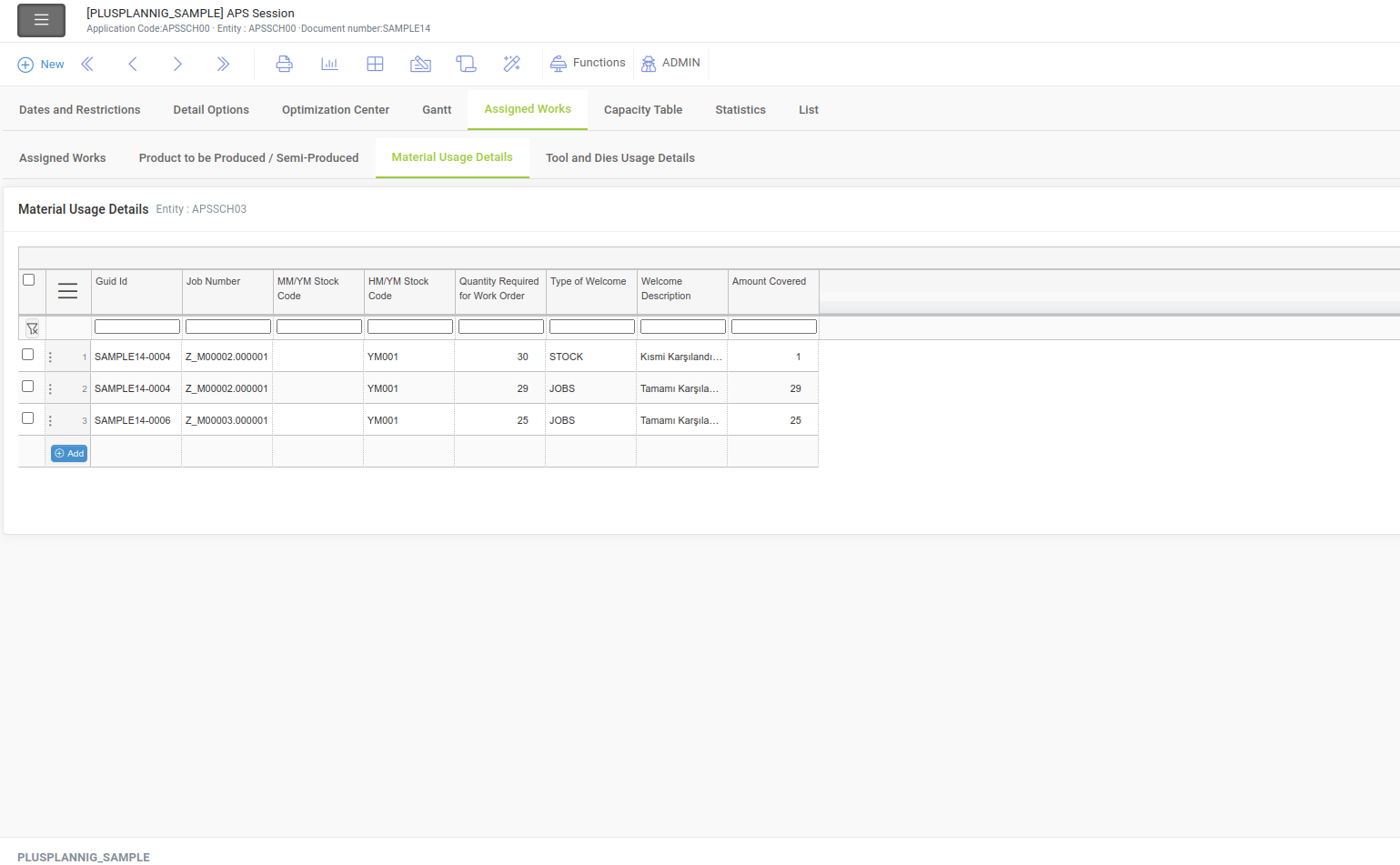

- Material Usage Monitoring: Monitors in detail how and how much materials are used in the production process. This enables accurate assessment of raw material consumption, waste and stock levels. Material usage data helps identify which materials are overused in production processes or areas where savings can be made.

- Tool Use Efficiency: Analyzes the use of production tools (machines, equipment). This analysis evaluates the vehicles' usage time, maintenance needs and performance. Using vehicles efficiently helps reduce breakdowns and optimize maintenance times.

- Performance Reporting: Creates detailed reports on material and tool usage. These reports provide managers and decision makers with a comprehensive view of how processes are working and inform strategic decisions.

- Inventory and Supply Management: Material usage analyzes help manage stock levels and the supply chain. Situations such as material shortages or overstock accumulations are optimized with timely intervention.