Hybrid Optimization

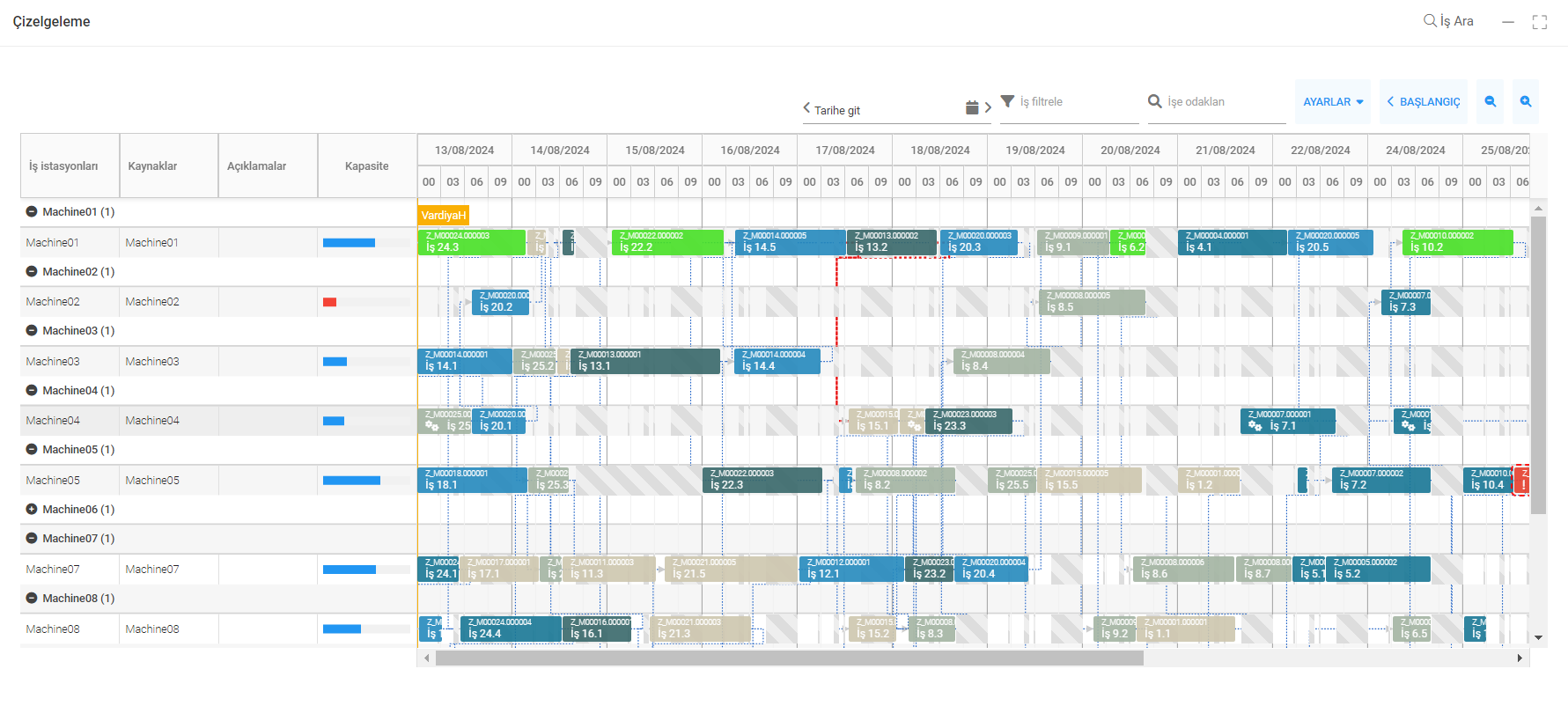

The Hybrid Scheduling feature enables more effective and efficient management of your production and planning processes. This feature optimizes resource utilization and improves delivery times by defining project start and end dates.

- Forward Scheduling: For make-to-order production, operations are scheduled forward from the beginning of the planning horizon. This method ensures a quick and efficient response to customer orders.

- Backward Scheduling: For make-to-stock production, operations are scheduled backward from delivery dates. This approach optimizes inventory levels, reduces costs, and streamlines production processes.

- Hybrid Scheduling: Enables both forward and backward scheduling within the same session, effectively coordinating production processes for both current orders and future requirements.