Reducing In-Workshop WIP Stocks

In modern manufacturing processes, managing Work In Progress (WIP) stocks within the workshop is crucial for increasing efficiency and reducing costs. WIP stocks refer to products that are being processed on a production line but are not yet complete. These stocks can accumulate due to imbalances in the production line, machine failures or maintenance periods, delays in material supply, operator shortages, or insufficient workforce skills. The Plus Planning software offers various strategies and tools to reduce WIP stocks:

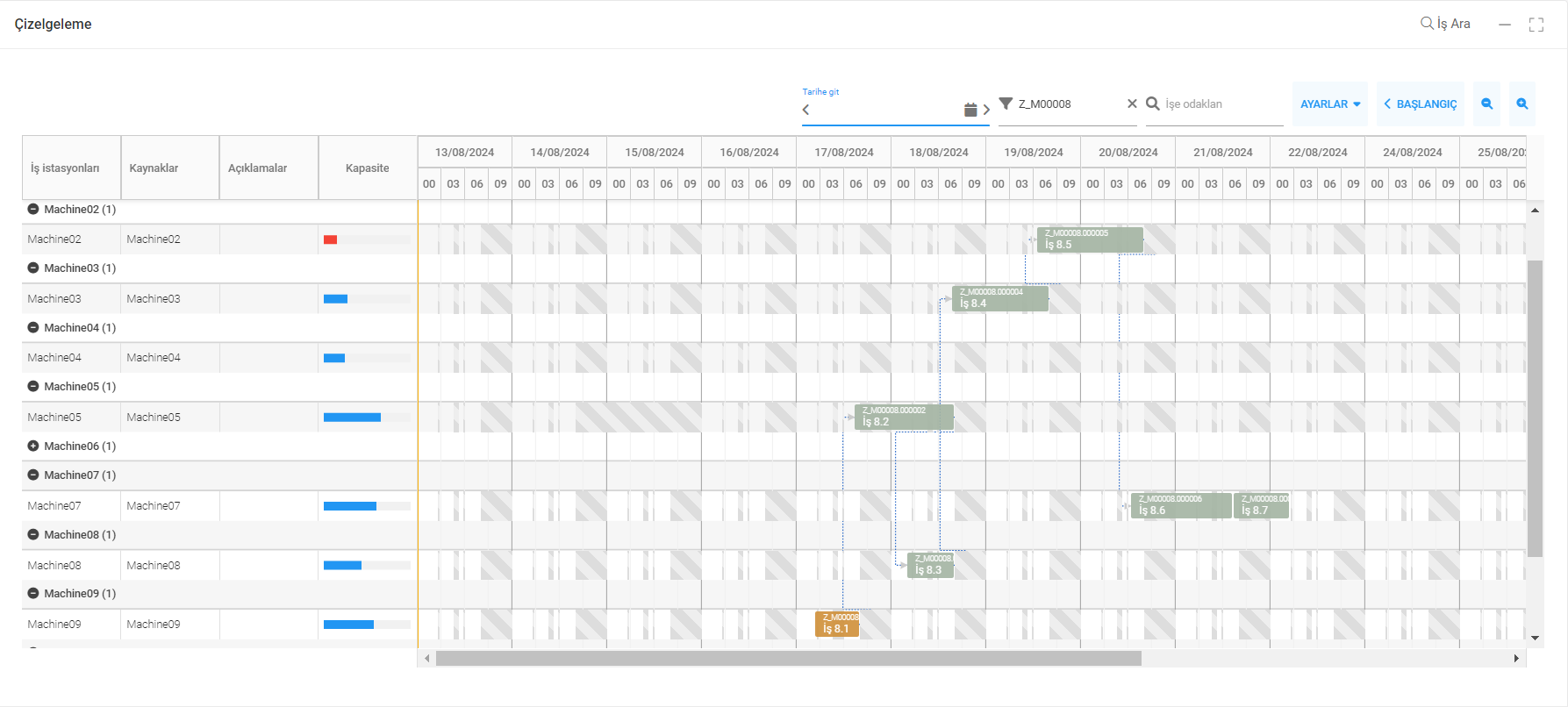

- Production Planning and Scheduling: Determines when and in what order each job will be processed. Balanced planning prevents bottlenecks and excessive stock accumulation on the production line.

- Real-Time Monitoring and Control: Any imbalance or issue can be detected and quickly addressed. Real-time data flow provides flexibility in the production process.

- Resource Optimization: Determines when and for how long each resource will be used, ensuring resources are utilized most efficiently. This prevents the accumulation of WIP stocks.

- Order Prioritization: Urgent and important orders are processed first, while low-priority orders are deferred. This ensures timely responses to customer demands while minimizing stock accumulations on the production line.

- Simulation and Scenario Analyzes: Analyzes performed on different production scenarios enable possible blockages and stock accumulations to be detected in advance and preventive measures to be taken.