Scheduling with Operator Constraints

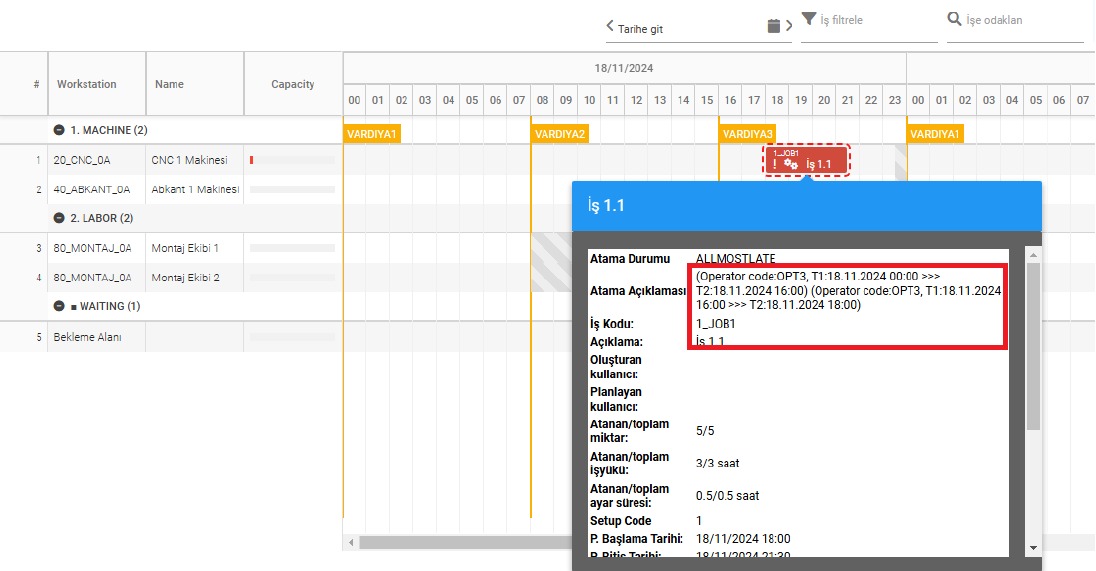

Defining operator constraints and managing them correctly in production processes increases the reliability of production plans. This feature allows scheduling based on operator skills, working hours and availability. Considering operator constraints directly affects production efficiency and operational continuity.

- Skill Based Scheduling: Work assignments are made according to the competencies the operators have. In this way, it is ensured that operations are carried out by people with the right skills and the rate of faulty production decreases.

- Management of Working Hours: Planning is made taking into account the operators' shift hours and days off. This minimizes overtime costs along with efficient use of workforce.

- Compliance Check: Appropriate operators are checked and assigned for certain operations. Thus, unplanned downtimes are prevented and production continuity is maintained.