Tool & Die Driven Scheduling

The use of tools and molds is always necessary for production environments. This requirement ensures that production processes are efficient, uninterrupted and of high quality. Correctly defining and managing tools and molds plays a critical role in optimizing processes.

- Resource Efficiency: Accurate definition of tool and mold quantities ensures the most effective use of production resources. This reduces production costs by reducing the idle time of resources.

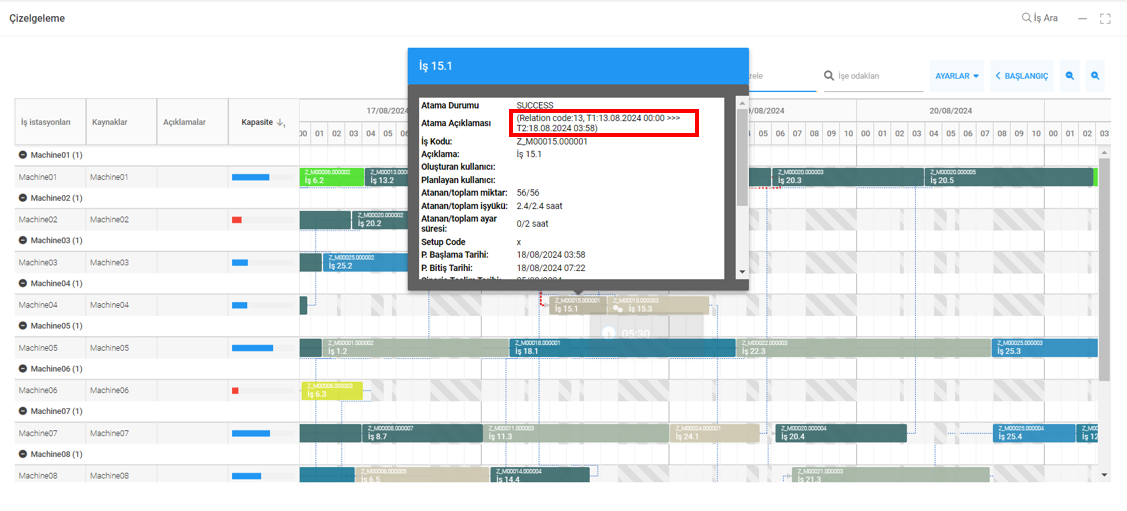

- Uninterrupted Production: By entering the dates when tools and molds can be used, waiting times on the production line are minimized and uninterrupted production is ensured. This ensures that production plans are more reliable and consistent.

- Operation Matching: Associating tools and molds with specific operations ensures that the right resource is used at each production stage. This speeds up the production process and improves product quality.